rockwell hardness test scale c|rockwell c hardness chart : importer The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the .

Resultado da 31 de ago. de 2023 · Distribuição de prêmios da Quina 6230. A Quina 6230 arrecadou a quantia de R$ 9.067.342,50 em apostas. Já o valor distribuído .

{plog:ftitle_list}

WEB14 de jun. de 2011 · Saiba como usar o Curitiba Consig, que substitui o Cartão Qualidade para os servidores municipais. Veja o manual, os prazos, as margens e os contatos .

The equation for the Rockwell hardness test for metals is below: d=depth from zero load point. N and s = various scale factors that can be found in the chart below. Rockwell A scale. Used to test: Tungsten carbide. Rockwell .Use these tables in selecting the scale that is appropriate for your application. Regular Rockwell Testing. In this test method, the minor (preload) is always 10 kgf. The major load may be any of the following loads: 60 kgf, 100 kgf, or 150 .

The Rockwell hardness testing method fulfilled every requirement. After 100 years, it’s still the best metal strength test method. The Rockwell C .Preliminary test loads (preloads) range from 3 kgf (used in the “Superficial” Rockwell scale) to 10 kgf (used in the “Regular” Rockwell scale). Total test forces range from 15kgf to 150 kgf (superficial and regular) to 500 to 3000 kgf .The Rockwell hardness of the test piece is calculated by subtracting the second load from the first and using the Rockwell formula. The resulting value is then translated to the Rockwell C .

The Rockwell hardness scale is designed to determine the hardness of materials like aluminum, thin steel, lead, iron, titanium, copper alloys, and cemented carbides. This article explains the procedure to perform the .Definition of the Rockwell hardness test method The Rockwell hardness test methods are described by a number of scales, characterized by a standard, an indenter type, and a load. Examples of Rockwell hardness test methods: .

s is either 0.001 mm or 0.002 mm, depending on the Rockwell hardness scale used N is either 100 or 130, depending on the Rockwell hardness scale used Rockwell hardness testing with United Testing Systems. Some of our most .

In the Rockwell hardness testing, the indenter applies the first load to the test piece. The indent is then measured, and the value obtained is used for the base calculations. This first load is removed, and another heavier load is applied to the indenter on the test piece. . The resulting value is then translated to the Rockwell C scale of .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload . The calculator has two modes — calculate and convert.The calculate mode is helpful if you have the indentation depth and want the Rockwell hardness number for either scale B or C. The convert mode is for converting Rockwell hardness numbers to a different scale like Brinell or Vickers.. The hardness data can not be presented in terms of a universal .

Scale C (carbide) testers are used for testing cemented carbides in the Rockwell A Scale, where tolerances of ± 0.20 of a Rockwell Hardness point are required. A specially selected “A” Brale penetrator is used to measure the hardness of cemented carbides in accordance with ASTM B 294 and the Cemented Carbide Producer’s Association (CCPA).

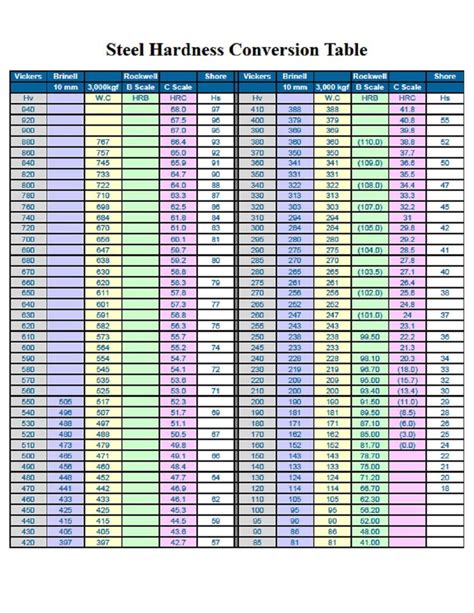

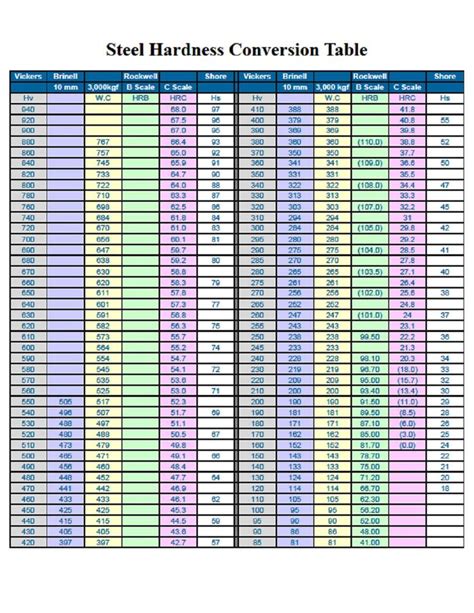

The majority of applications are covered by the Rockwell C and B scales for testing steel, brass and other metals. However, the increasing use of materials other than steel and brass, as well as thin materials, necessitates a basic knowledge of the factors that must be considered in choosing the correct scale to ensure an accurate Rockwell test.A widely used variant of the Rockwell hardness test is the superficial Rockwell test, wherein the minor load is 3 N and the major loads are 15, 30, or 45 N.Further details on the Rockwell superficial hardness scales are available in the relevant ASTM standards (ASTM 1984).The Rockwell hardness values are expressed as a combination of hardness number and a scale .Rockwell hardness test using Rockwell hardness scale is one of the extensively used and accurate hardness test methods prevalent in industries for thin steel, lead, brass, zinc, aluminum, cemented carbides, iron, titanium, copper alloys, and certain plastics.In conversion scales, common terms which should be first understood are scales, symbol, indenter and load or test force. All of these tables are based on these terms. For any hardness test, these tables are used for conversion of values from one test to another to get accurate results. . Rockwell C Hardness Range Hardness Conversion Chart for .

No wonder, Rockwell hardness testing scales are globally used and are the most popular ones. It is used for static hardness testing of the material. We have described thoroughly in this article the scales of the hardness test. Just follow the standard scale tables and rules to get the accurate values of the hardness of your test material.

The Rockwell scale characterizes the indentation hardness of materials through the depth of penetration of an indenter. It is typically used in engineering and metallurgy and is most common in the USA. Its commercial popularity arises from its speed, reliability, robustness, resolution and small area of indentation.Rockwell Hardness Testing File Sets . Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale. Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. The scale follows an even subdivision of 0.002 mm (2 µm), so that reaching half the reference depth also corresponds to half the maximum hardness value (Rockwell hardness value 50). When diamond cones are .

What is the Rockwell Scale? Rockwell hardness testing is the most commonly used hardness testing method to measure the permanent depth of an indentation, which is finally compared to the Rockwell scale to derive the .

Metallic materials — Rockwell hardness test — . 4.1 The Rockwell hardness for the scales A, C and D is denoted by the symbol HR preceded by the hardness value and completed by a letter indicating the scale. EXAMPLE 59 HRC = Rockwell hardness of 59, measured on the C scale.

A scale indicating the hardness of materials, first used in 1919, when it was invented by Stanley P. Rockwell.The measurement has no units. The symbol is HR followed by a letter indicating one of a number of possible scales, described in the table below.Steel Hardness conversion calculator: Brinell Hardness HB: Rockwell C - HRC: Rockwell B - HRB: Vickers - HV : Enter a figure into any of the fields and click calculate, the nearest values in each scale is shown, or zero if out of range. Values are approximate and for guidance only.The connection between hardness and carbon content is clearly visible in the example below: the higher the carbon content, the higher also the HRC of various types of White Steel: White Steel 1 / 63 HRC / C = 1.25-1.35 % White Steel 2 / 61-62 HRC / C = 1.05-1.15 % White Steel 3 / 60 HRC / C = 0.80-0.90 % Measuring hardness There are several .

Set includes six files and a chart to convert to Vickers scale. It is an economical way to determine the hardness of steel on the Rockwell C-scale.Handles are marked with Rockwell hardness values. If a file can scratch your material, then your material is softer than the file. If a file cannot scratch your material, then your material is harder than the file.A variety of hardness-testing methods are available, including the Vickers, Brinell, Rockwell, . Rockwell A,B,C) Struers hardness conversion table (Vickers, Brinell, Rockwell B,C,D) This page was last edited on 18 December 2023, at 21:15 (UTC). Text is available under the Creative .The table below converts Brinell Hardness to Rockwell Hardness scales and vice versa, then compares those to the approximate tensile strength that those scales indicate. Brinell Hardness: . FREE Mill Test Reports Save on your Mill Test Reports and Certs of Conformance. They're always FREE at OnlineMetals.com. Learn More. Knowledge Hub .

In Rockwell hardness testing, HRA, HRB, and HRC represent three different scales: Scale A, Scale B, and Scale C. The Rockwell test is a common indentation hardness test. All three scales begin with an initial pressure of 98.07N (10kgf), and the hardness value is calculated based on the depth of indentation.Basic principle and practical procedure of the Rockwell hardness test - Testing machine, test piece, conical diamond indenter - Basic principle, hardness d.the Rockwell hardness test ( scales and hardness range according to Table 1) for metallic materials. NOTE — For certain materials, the hardness range may be narrower than those indicated. 2 REFERENCE The following Indian Standard contains provisions which through reference in this text, constitutes

rockwell steel hardness chart

Rockwell Hardness Test (HRC) C scale (HRA) A. 60kgf diamond conical indenter (HRB) B. 100kgf diameter. 1.6mm (1/16ln) ball . Rockwell Hardness test is the most widely used method but in some cases Vickers Hardness testing method has to be used especially when thin parts have to be tested. It is important to look up the hardness scale .

tester perfume bottles

tester vs bottle

El ahegao (アヘ顔 ) —a veces escrito como «ahe gao», «ahego» o «cara ahegao», también llamado O-Face — es un término originario del idioma japonés que describe la expresión facial que muestra un estado rotundo de placer, usualmente de carácter sexual, en el rostro de un individuo . Ver mais

rockwell hardness test scale c|rockwell c hardness chart